Rethink food waste management: When the end of the line is just the beginning.

We asked Jeff Schmitz, Commercial Manager at Green Field Solutions, about what landfill alternatives consumer packaged goods companies have and how to choose the best one — or more than one — for the final disposal of their various waste streams.

What are common landfill alternatives?

Repurposing co-products, composting organics, recycling reusable materials and converting waste to energy are all options we look at as we assess our clients’ waste materials. There are a lot of companies that have multiple waste streams like cookies, crackers, bread items, dairy (cheese, milk, etc.), candy, chocolate, and even gum.

GFS’s entrepreneurial team of creative problem solvers provide a full banquet of sustainable waste mitigation services focused on food waste, solid waste and recyclables. We help CPG companies manage their waste streams in sustainable ways with a one-stop-shop approach.

How are waste management solutions identified?

Green Field Solutions manages a wide variety of waste products from all different types of food manufacturing facilities. Through research, our scientists determine the unique nutritional profiles of each organic material. Then, we can identify best applications, ideal consumers, appropriate geographies and marketable products.

Some waste products are very nutritious and can go into animal feed. We’d much rather see food waste stay in the human food chain this way. However, when materials aren’t suitable for animal feed production, it’s our job to find the right partners to compost, recycle or otherwise manage those materials in the best possible way.

Let’s say repurposing, composting and recycling aren’t viable options for any particular waste stream. Then what? There may still be landfill alternatives for those materials, too. Waste-to-energy is a common non-landfill option for solid waste. For companies with sustainability targets to eliminate landfill usage entirely, waste energy regeneration may be the only sustainable substitute.

How does energy recovery work?

There is a lot of bioenergy going on in the United States. Green Field Solutions, for example, manages millions of pounds of by-products from the brewing industry every year. In addition to ending up in pet food, the distillation process creates hundreds of thousands of gallons of high quality, advanced biofuels ethanol.

There is a lot of bioenergy going on in the United States. Green Field Solutions, for example, manages millions of pounds of by-products from the brewing industry every year. In addition to ending up in pet food, the distillation process creates hundreds of thousands of gallons of high quality, advanced biofuels ethanol.

There are multiple forms of energy recovery. The ones listed below are recognized for reducing greenhouse gases. Beyond this list, we continue to explore how different food products can produce energy for natural gas, biodiesel or ethanol.

- Corn-based ethanol is the most common biofuel in use today.

- Waste-to-energy is an option where solid waste is incinerated to produce steam and ultimately electricity.

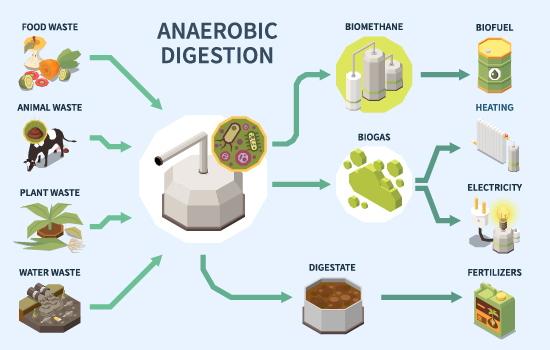

- Anaerobic digestion is when a biodigester breaks down organic materials and produces biogas as a by-product.

How does geography impact recycling?

Transportation is the most dominant cost factor in our entire industry. That’s why we still see a lot going into the landfill. The economics of hauling waste any substantial distance just isn’t viable. It is upon us to find something that makes geographic and economic sense. As we open doors and find the right partners for our clients’ waste streams, we simplify their waste management processes and create long-term value for them.

That’s what GFS is all about, helping CPGs manage their waste streams in the most sustainable ways.

Jeff is a home-grown Midwesterner, born and raised in Minneapolis. He began his career in agriculture at Central Soya on the floor of the Minneapolis Grain Exchange, followed by many years at the Chicago Board of Trade. After moving to St. Louis to work for Bunge North America, he joined International Companies and Green Field Solutions in 2016. It’s a move he calls: “The absolute best career decision of my life!”